Innovative Wastewater Solutions

EvaporationWorks — Engineering the Future of Evaporation

Evaporation. Aeration. Bioremediation.

Evaporation Systems for Complex Wastewater Challenges

Produced Water Evaporation

Cost-effective and compliant solutions using patented rotary atomization to rapidly evaporate produced water while meeting zero discharge requirements.

Process Water Treatment

Scalable systems designed for commercial and industrial needs: minimizing maintenance, energy costs, and environmental impact through accelerated evaporation technology.

Industrial Wastewater

Custom evaporation units designed for reliability in isolated locations, offering efficient wastewater management without dependence on large infrastructure.

Regulatory Compliant for Demanding Industries

Choosing our solutions means opting for quality and reliability. Our systems are designed to optimize efficiency and provide sustainable options for industrial wastewater management. With a focus on innovation and customer needs, we offer robust solutions that withstand the demands of various sectors.

Municipal Wastewater

✓ Streamline the treatment of effluent from lagoons

✓ Lower operational burden on small municipalities

✓ Scalable systems for changing compliance needs

Oil & Gas

✓ Treat produced water efficiently onsite

✓ Lower disposal costs and reduce truck hauls

✓ Regulatory-compliant Accelerated Evaporation

Mining

✓ Manage process water in rugged terrain

✓ Avoid costly pond expansions

✓ Dependable performance in harsh climates

Our Mission

Reducing Wastewater Volume Through Accelerated Evaporation

We help industrial and municipal clients solve complex wastewater challenges through compliant evaporation technologies. Our patented systems not only reduce water volume, they also reduce liability and operational costs.

Interested in Air Emissions Data?

What Our Clients Say

Built for Industrial Demands

Patented Evaporation Technology

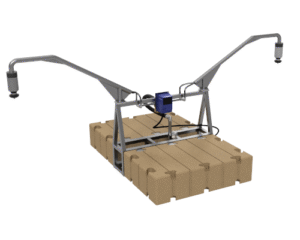

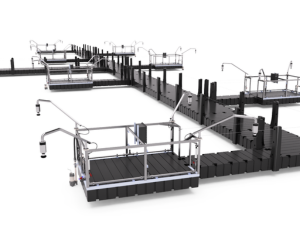

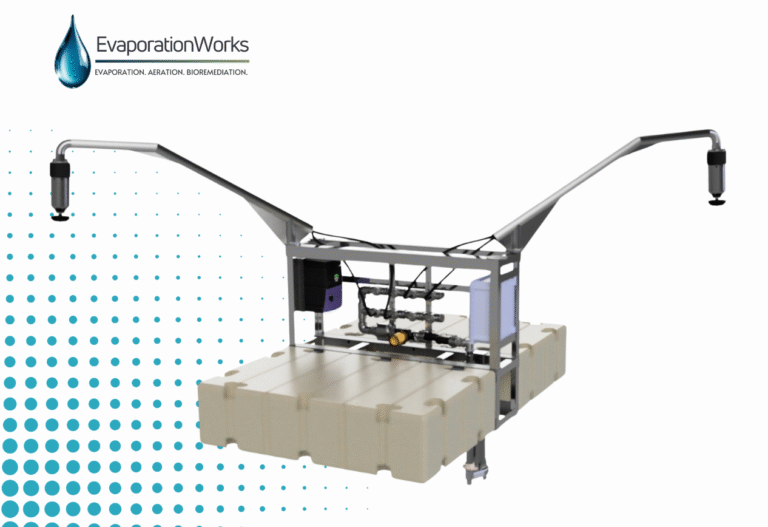

Varimax™ Series

Scalable Units with Walkways for Safe and Easy Maintenance

Designed for your specific project to maximize evaporationWhy EvaporationWorks?

- Regulatory Compliant

Supports discharge permits, waste minimization goals, and zero-liquid discharge (ZLD) planning. - Low-Cost Operation

Designed for minimal chemical input and low energy use. Integrated Treatment Support

Works in tandem with aeration and bioremediation to improve performance and reduce fouling.Patented Evaporation Platform

High flow-rate atomizers of 12-20 GPM each.Variable-Speed Atomization

Automatically adjusts droplet size without changing flow rate to maintain evaporation under changing conditions.Custom Configurations

Systems are sized to site-specific flow and environmental conditions—not overbuilt or generic.

Ready to Start? Let’s Talk.

Get a customized quote or download our application-specific fact sheets to see how EvaporationWorks can support your operations.

Get in Touch With Us

Call

Sales: 888-501-2126

Customer Support: 813-730-7900

Office: +1-813-223-9000

contact@evaporationworks.com

Office Locations

Tampa

Grand Junction

Houston

Plant City